IN THIS COURSE YOU WILL LEARN…

+ The terminology, vocabulary, and fundamental concepts.

+ To understand the code organization, scope, and most important sections.

+ To design and calculate all the main components of S&T Heat Exchangers.

| 242 Students |

| Video: English |

| Certificate of Training |

+ The terminology, vocabulary, and fundamental concepts.

+ To understand the code organization, scope, and most important sections.

+ To design and calculate all the main components of S&T Heat Exchangers.

120 hours of self-guided training through our platform, without scheduled sessions, to progess at your own pace.

120 hours of self-guided training through our platform, with no scheduled sessions, the possibility to ask questions to the instructor, and progress at your own pace.

15 hours of live virtual classes with the instructor. Classes are primarily practical, focusing on the resolution of real-life cases.

Pay for this course in three interest-free installments with PayPal. More information.

This course can be credited towards completing the Master. By completing the other three corresponding courses (TEMA, ASME VIII, and API 650), and doing the Final Project, you can obtain the Master’s Certificate. Write to us for more information.

This course is available in an in-company modality, tailored exclusively for your organization, adapting dates, schedules and contents to perfectly suit your needs. Reach out to us detailing the training needs of your team, and we will contact you to coordinate it.

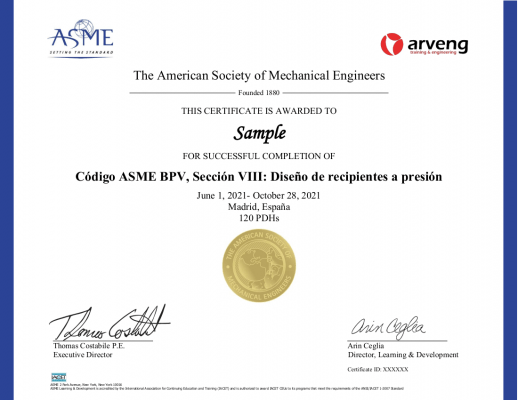

Upon successful completion of the course participants will earn 120 PDH’s, equivalent to 12 CEU’s (Guided) or 15 PDH’s (Live).

This recognition can only be obtained with the ASME certificate.

PDH: Professional Development Hour

CEU: Continuing Education Unit

*If you are not interested in obtaining an ASME certification after completing the course, we can offer you a discount. Contact us for more details!

This course is intended for graduates (or soon to be), designers, freelancers, technicians and engineers involved in: calculation, design, selection, manufacturing, safety, quality and maintenance of systems and equipment in industrial processes.

Previous knowledge of this subject is not required to attend to the course.

The main objective of this course is to transfer to participants the theoretical and practical skills required in projects, obtained from experience and sound engineering practices.

At the end of the course, participants will be able to design the main parts of a Shell & Tube Heat Exchanger under all types of possible loadings, stored product, internal / external pressure, wind and earthquake among others. At the end of the course participants will:

To enroll in this course you have to follow the below steps:

Yes! Contact us indicating your needs and we will find the most convenient alternative for you.

To enroll a 3rd paty/more than one person you have to follow the below steps:

Please, send us your query and we will reply as soon as possible.

Average Rating

Detailed Rating

| Stars 5 |

|

8 |

| Stars 4 |

|

1 |

| Stars 3 |

|

0 |

| Stars 2 |

|

0 |

| Stars 1 |

|

0 |

You must be logged in to post a review.

| 242 Students |

| Video: English |

| Certificate of Training |

Mario Rubio

The course contents are very clear and easy to understand. Moreover the way of teaching and delivering is very nice. Also the course is very beneficial for me while doing my projects.

Belkacem K.

Une explication de la norme TEMA et les normes de conception des échangeurs c’est vraiment cool

[An explanation of the TEMA standard and exchanger design standards is really cool]

Abdullah A.

I like the case studies and hope to be more in future. Thanks a lot

Juhyung

Thank you for offering a great course. It was really helpful!

isurs

Very good course! Very detailed and well oriented. And Javier is also available for any kind of doubt or question.

jack_p

I’ve really enjoyed this course. I study this subject years ago and I remembered it as very dense, but with all the available material and the assinments contents are easily acquired. Highly recommendable! Thanks!

peter.jk

design of mechanical equipment could be really dense topic, not the case of this course. I’ve got experience on the subject and I’ve enjoyed the course a great deal. Super well structured with tons of material. Thanks.

Matt

It is really easy to navigate through the contents, course instructions are very clear. Solved calculation sheets a very useful to double check the designs. Cheers, Matt.

giulete

The Arveng team was very kind, giving me extra time to finish this course. Thank you!