Design of mechanical equipment (Self-guided)

| 514 Students |

| Duration: 240 hours |

| Lectures: Available! |

| Video: English |

| Certificate of Training |

In this course you will learn......

+ The the organization of the codes, vocabulary and fundamentals.

+ The knowledge for design of the main mechanical equipment used in most industrial plants, safe an economical.

WITH THE ACCESS TO THE COURSE YOU GET:

Course access: 12 months

This level has been developed to be completed in 6 months. However, the campus will be open 12 months to give you more time.

Consultation forum

Queries will be channeled via dedicated forums, our instructors will answer as soon as possible!

Instructor available

An specialist Instructor will be available throughout the entire duration of the course.

Downloadable resources

Study notes, case studies and extra material are downloadable for future reference.

Summary videos

Each lesson includes a summary video with then fundamental concepts dealt with in that lesson for better understanding.

Lesson included

All the lessons indicated in the CONTENTS tab are included.

Assessment questions

Multiple-choice assimilation questions and cases are presented in each lesson to fix fundamental concepts.

Case studies

This is a “hands-on” course. Real cases (and solved) are presented to be developed with the course material.

Calculation sheets

Specific spreadsheets have been developed to simplify the calculation process. Calc sheets are downloadable.

Certificate of approval

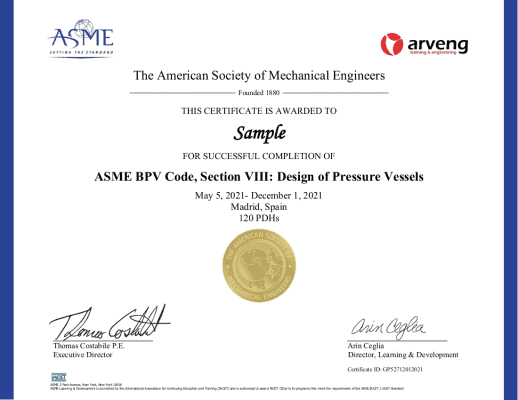

A certificate of approval issued by ARVENG or ASME (your choice) will be submitted upon completion.

FREQUENTLY ASKED QUESTIONS (FAQ’s):

How can I enroll in this course?

To enroll in this course you have to follow the below steps:

- Choose the course you need from the drop-down menu (top right hand corner of the web).

- Click on “Add to cart”

- Complete the purchase process using the payment options available.

- You will receive a confirmation email.

- Start training your skills!

Can I register and pay an online course for a 3rd party/more than one person?

To enroll a 3rd paty/more than one person you have to follow the below steps:

- Change the number of products of your cart (1 by default):

a. Change the number of products before clicking on “Add to Cart”.

b. Directly on the cart screen, there is a button where you can increase or decrease the amount of products to buy. - State the Name and Surname of the participants in the observations field when completing the purchase.

Are there discounts for groups/companies?

Yes! Contact us indicating your needs and we will find the most convenient alternative for you.

COURSE LED BY AN ASME AUTHORIZED INSTRUCTOR

You can study the structure, contents and methodology before enrolling.

Pay for this course in three interest-free installments with PayPal. More information.

Begin at your convenience, progress at your own time and own pace.

The course follows the “learn by doing” methodology. Different challenges are presented in the form of practical case studies. With the help of the Study Notes and with the assistance of the instructor, participants will progress gradually throughout the course.

Who should attend?

This course is intended for graduates (or soon to be), designers, freelancers, technicians and engineers involved in: calculation, design, selection, manufacturing, safety, quality and maintenance of systems and equipment in industrial processes.

Previous knowledge of this subject is not required to attend to the course.

Training objetives

The main objective of this course is to transfer to participants the theoretical and practical skills required in projects, obtained from experience and sound engineering practices.

What to expect?

Course participants will gain the knowledge for design of the main mechanical equipment used in most industrial plants, safe an economical.

At the end of the course, participants will be able to design the main parts of the mechanical equipment proposed.

- Know the organization of the codes and acquire the vocabulary and fundamentals.

- Benefit from the lessons learned and best engineering practices.

- Learn to select materials.

- Define the fluid velocity and obtain the min. diameter for a pipe and a known flow.

- Select the different components of a piping system.

- Calculate the required thickness of the pipe under internal pressure.

- Design and calculate stiffening rings for a pipe under vacuum.

- Learn to perform stress and flexibility analysis on systems using simplified methods.

- Calculate buried piping systems.

- Become familiar with the basics of a pipe layout.

- Learn to interconnect pipes with the main equipment.

- Understand the main differences between the types of supports.

- Learn to select rigid and spring supports.

- Learn to design and calculate the main parts of a pressure vessel.

- Understand and apply the Joint Efficiency concept.

- Learn to deisign Legs, Skirs and Saddles.

- Define the wind profile and seismic loads.

- Design and calculate stiffening rings for a pressure vessel under vacuum.

- Learn to design different types of nozzles: built up, self-reinforced, integral.

- Learn to design Non-Standard Flanges.

- Understand the different configurations of Heat Exchangers.

- Learn to design a heat exchanger from a mechanical point of view.

- Design the tube bundle and calculate the thickness of the tubesheet.

- Learn to verify the thickness of the transfer tubes.

- Learn to design and calculate the main parts of a storage tank.

- Design and calculate stiffening rings for the tank wall.

- Define the anchorage requirements due to earthquake and the wind.

- Understand the main differences between roof types.

- Learn to design and calculate fixed roofs and their internal support structure.

- Obtain the seismic spectrum, wind loads and verify the overturning moment.

- Design anchor bolts of static equipment due to combined loads.

TRY THIS COURSE BEFORE ENROLLING!

You can study the structure, contents and methodology before enrolling. You can also watch the introductory videos and solve the test in Lesson 1! Leave us your contact information and we will send the instructions to access the Virtual Campus:

CONTENTS AND STRUCTURE OF THE COURSE: 240 HS

PART I (120 hs):

Classification & Characteristics

Design Conditions

Load Types | Pressure | Wind | Seismic

Material Selection

Corrosion Types | Materials Designation

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

Divisions | Organization | Scope

Piping Specification

Piping | Fittings | Piping Class

Thickness Calculations

ASME B31 Equations | Available Thicknesses

Piping Layout

Plot Plan | Equipment Location

Stress & Flexibility Assessment

Thermal Loads | Simplified Calculations

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Thicknesses Calculation

Divisions | Organization | Scope

Joint Efficiency

Joint Category | Efficiency Values

Internal Pressure Design

Shell | Heads | Conical Transitions

External Pressure Design

Support Lines

Stiffening Rings

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Internal Pressure Design

Divisions | Organization | Scope

S&T Heat Exchangers Configurations

Tubes Arrangement | Number of Passes

Shell Design

Cylindrical Shells | Types of Heads

Tube Bundle Design

Tubesheet | Bundle Structure | Joining Methods

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Tubesheet & Tubes Design

Divisions | Organization | Scope

Tank Shell Design

One-Foot Method | Fabrication Requirements

Tank Bottom Design

Plates Distribution | Annular Plate

Fixed Roof Design

Roof Types | Configuration | Thicknesses

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Design of Tank Shell & Bottom

PART II (120 hs):

Fluid Flow | Energy Conservation principle

External Pressure Design

Support Lines | Stiffening Rings

Design of Buried Piping

Types of Loads | Stresses Verification

Equipment Interconnection

Layout Importance | Good Practices

Supports Design

Location | Supports Selection

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Optimal Diameter & Pressure Loss

Trays | Supports

Lifting Lugs

Nozzle Design

Flange Selection | Nozzle Neck | Reinforcement Pads

Wind & Seismic Loads

Vessel Loads | Vibration Period

Supports for Vertical Equipment

Design of Legs & Skirts | Anchor Bolts

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Nozzle Design

Hub Design | Calculation Procedures

Design of Body Flanges (Non-Standard)

Design Sequence | Sound Practices

Supports for Horizontal Equipment

Design of Saddles | Anchor Bolts

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Design of Body Flanges (Non-Std)

Shell Stability | Wind Girders

External Pressure

Design considerations | External pressure verification |

Tank Shell verification

Nozzle Design

Configuration | API 650 Code Requirements

Wind Loads

Wind Pressure on the Shell | Overturning Moment

Seismic Loads

Base Shear | Overturning Moment

Anchor Bolts

Number of Bolts | Chairs Design

Proposed Case Studies

- Self-Assessment Quiz: Multiple choice questions

- Case Study: Nozzle Design

TRY THIS COURSE BEFORE ENROLLING!

You can study the structure, contents and methodology before enrolling. You can also watch the introductory videos and solve the test in Lesson 1! Leave us your contact information and we will send the instructions to access the Virtual Campus:

EXAMPLE OF A CERTIFICATE ISSUED BY ARVENG:

EXAMPLE OF A CERTIFICATE ISSUED BY ASME:

Upon successful completion of the course participants will earn 240 PDH’s, equivalent to 24 CEU’s.

This recognition can only be obtained with the ASME certificate.

PDH: Professional Development Hour

CEU: Continuing Education Unit

REQUEST MORE INFORMATION!

Please send us your query and we will reply as soon as possible.

About Instructors

Reviews

Average Rating

Detailed Rating

| Stars 5 |

|

14 |

| Stars 4 |

|

6 |

| Stars 3 |

|

0 |

| Stars 2 |

|

0 |

| Stars 1 |

|

0 |

Add a review Cancel reply

You must be logged in to post a review.

| 514 Students |

| Duration: 240 hours |

| Lectures: Available! |

| Video: English |

| Certificate of Training |

WhatsApp

WhatsApp

Emilia C.

A pleasant experience in addition to learning new things that will be useful to us in the exercise of our profession.

Susan S.

I highlight the continuous attention on the part of the tutor when it comes to resolving doubts. Complete course and very clear when it comes to following it.

Alexander T.

The content is very broad and the explanations are very detailed. I recommend it.

Harrison A.

Clear, precise and highly topical training in the practical examples it offers.

Jane U.

The tutor’s attention has been very good, the operation of the platform is excellent, as well as the clarity and material provided in the course. I recommend it.

Richard A.

Very practical course adapted to initial objectives. 100% recommended.

Lewis H.

The experience has been totally satisfactory, the structure, duration and scope are appropriate.

Hakan G.

Overall, this course was very helpful and I really appreciate your help and support. It helped me out to remind some details, learning some more details and making practice for some topics. Thanks to everyone who has a part of this fruitful course.

richardbf

I’d like this course to be more comprehensive on some topics, but I guess I will have to enroll on other courses to keep learning about them. Good course, anyway.

Megan

I like the structure of this course, and the fact that you can complete it by modules at your own pace.

George H

A lot of exercises to practice all the theory in this course… It’s a very complete course.

amy

Very good course. I am looking forward to go deep in some concepts with another Arveng courses.

PaulAnd

My first time following an online course… And I’ll repeat for sure! Lots of materials to practice each lesson.

S.Bruce

Great course, teacher’s responses a fast and comprehensive.

joe-curbs

I’m brand new to this field and the course have helped me a great deal. Even when this is a tough subject, the structure and assignments allow you to go step by stop at your own pace. Thanks to the Arveng team.

kevin.francis

Very good course. Arid topics, very well broken down. Arveng Admin has been really flexible with me, thanks! Kevin.

fabiofidaro

Very comprehensive course. It coveres a lot of equipments, designs and configurations. Real data sheets and case sutides are the added value of this course. I recommend this course 100%.

susan.dobson

Excellent course! Will repeat for sure. Thanx.

ed-harrys

Loved the structure of the course, even better assignments. This is trully a self-guided course, course very easy to follow. Ed

patrick.ilja

Great compilation of design requirements for the main mechanical equipment in a plant. I was surprised by the promptness of the instructor and elaborated responses. Will recommend this course for sure.