API 510 | Pressure Vessels Inspection and Repair (Live Course)

| 39 Students |

| Duration: 16 hours |

| Certificate of Training |

When and where?

Dates: To be defined

Time: To be defined

Place: To be defined

In this course you will learn......

+ The vocabulary, terminology, and fundamental concepts of the API 510 code.

+ Inspection, Examination, and Pressure Testing Practices and intervals and frequency of inspection.

+ Inspection data evaluation and recording.

+ Repairs and re-rating.

-

Instructor-led training course

-

Downloadable study notes

-

Solved case studies

-

Solved examples

-

Reference material

FREQUENTLY ASKED QUESTIONS (FAQ’s):

How can I enroll in this course?

To enroll in this course you have to follow the below steps:

- Click on “Add to cart”

- Complete the purchase process using the payment options available.

- You will receive a confirmation email.

- On the call date, start training your skills!

Can I register and pay for a live course for a 3rd party/more than one person?

To enroll a 3rd party/more than one person you have to follow the below steps:

- Change the number of products of your cart (1 by default):

a. Change the number of products before clicking on “Add to Cart”.

b. Directly on the cart screen, there is a button where you can increase or decrease the amount of products to buy. - State the Name and Surname of the participants in the observations field when completing the purchase.

Are there discounts for groups/companies?

Yes! Contact us indicating your needs and we will find the most convenient alternative for you.

Terms and conditions

An applicant who withdraws from the course 2 working days or less prior to the course start date will entitle ARVENG to retain 10% of the tuition fee as an administration fee. Once the course has started, no refund will be made.

All ARVENG courses are subject to possible changes of dates that will be communicated as soon as possible. ARVENG is not responsible for the expenses incurred for travel-related contracts (hotels and flights), so we recommend that they are not made well in advance and if they are made, they should be contracted with cancellation or change insurance.

Get a discount for early payment if you register 15 days before the start of the course, write to training@arvenggroup.com and we will inform you how to proceed.

Instructor-led training course in adult learning format.

The course follows the “learning through experience” methodology. A series of discussions, individual exercises and simplified case studies provide practical knowledge to implement in the field. With the help of the Study Notes and with the assistance of the instructor, participants will gradually progress through the course.

Who should attend?

This course is intended for graduates (or soon to be), designers, freelancers, technicians and engineers involved in: calculation, design, selection, manufacturing, safety, quality and maintenance of systems and equipment in industrial processes.

Previous knowledge of this subject is not required to attend to the course.

Training objectives

The main objective of this course is to transfer to participants the theoretical and practical skills required to inspect and repair pressure vessels. This knowledge has been obtained from experience and sound engineering practices.

At the end of the course, participants will have a clear vision of the requirements of these regulations.

What to expect?

- Get familiar with the vocabulary, terminology and fundamental concepts.

- Learn the organization of the code, scope, and fundamental sections.

- Benefit from lessons learned and best practices from different international projects.

- At the end of this training participants will be able to define the main requirements necessary for the repair of pressure equipment and piping:

- Inspection Organization

- Inspection, intervals, frequency.

- Pressure testing

- Repair and alteration

- Equipment rerating

CONTENTS AND STRUCTURE OF THE COURSE: 16 HS

Inspection, Examination and Pressure Testing Practices

Inspection Plans

Risk based inspection (RBI)

Deterioration and failure mechanisms

Types of inspection

Condition Monitoring Locations, CML

Pressure Testing

Test methods and specific inspections

Inspection of In-service Welds

Inspection and repair of flanged joints

Inspection and repair of S&T heat exchangers

Intervals, frequency and extent of inspection

Inspection extent

Risk Based Inspection (RBI)

External inspection

Internal, on-stream and thickness measurement inspections

Pressure relieving devices

Review of inspection recommendations

Inspection data evaluation and recording

Corrosion rates determination

Remaining life calculations

MAWP determination

Analysis of corroded regions

Fitness for service evaluations (FFS)

Required thickness determination

Reports and Records

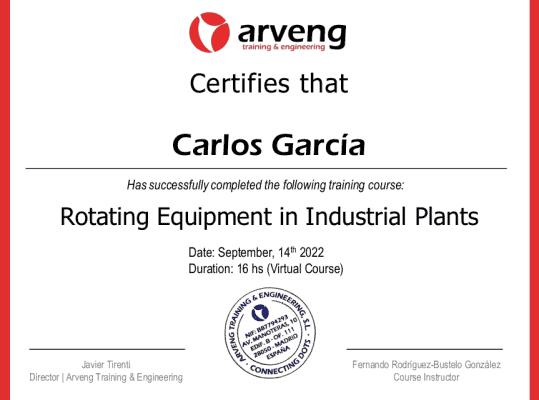

EXAMPLE OF A CERTIFICATE ISSUED BY ARVENG:

REQUEST MORE INFORMATION!

Please send us your query and we will reply as soon as possible.

About Instructors

Reviews

Average Rating

Detailed Rating

| Stars 5 |

|

2 |

| Stars 4 |

|

0 |

| Stars 3 |

|

0 |

| Stars 2 |

|

0 |

| Stars 1 |

|

0 |

Add a review Cancel reply

You must be logged in to post a review.

| 39 Students |

| Duration: 16 hours |

| Certificate of Training |

WhatsApp

WhatsApp

Martin G.

Very useful theoretical and practical knowledge. The tutor responds quickly to doubts/queries made.

Richard E.

Until now, the content of the topics I have seen seems excellent to me since I have learned new things and refreshed others. I hope to continue exploring other topics that I want to know about.