IN THIS COURSE YOU WILL LEARN…

+ The terminology, vocabulary, and fundamental concepts.

+ To understand the code organization, scope, and most important sections.

+ To design and calculate all the main components of Pressure Vessels.

| 978 Students |

| Video: English |

| Certificate of Training |

+ The terminology, vocabulary, and fundamental concepts.

+ To understand the code organization, scope, and most important sections.

+ To design and calculate all the main components of Pressure Vessels.

120 hours of self-guided training through our platform, without scheduled sessions, to progess at your own pace.

120 hours of self-guided training through our platform, with no scheduled sessions, the possibility to ask questions to the instructor, and progress at your own pace.

15 hours of live virtual classes with the instructor. Classes are primarily practical, focusing on the resolution of real-life cases.

Pay for this course in three interest-free installments with PayPal. More information.

This course can be credited towards completing the Master. By completing the other three corresponding courses (TEMA, ASME VIII, and API 650), and doing the Final Project, you can obtain the Master’s Certificate. Write to us for more information.

This course is available in an in-company modality, tailored exclusively for your organization, adapting dates, schedules and contents to perfectly suit your needs. Reach out to us detailing the training needs of your team, and we will contact you to coordinate it.

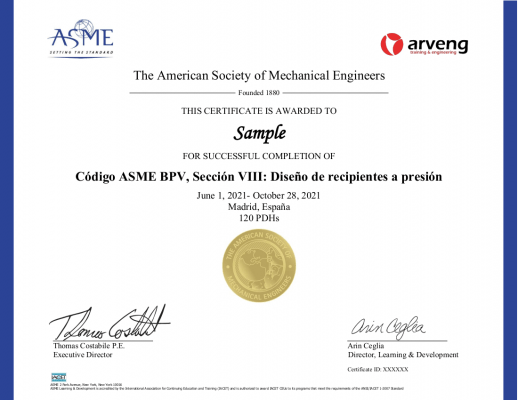

Upon successful completion of the course participants will earn 120 PDH’s, equivalent to 12 CEU’s (Guided) or 15 PDH’s (Live).

This recognition can only be obtained with the ASME certificate.

PDH: Professional Development Hour

CEU: Continuing Education Unit

*If you are not interested in obtaining an ASME certification after completing the course, we can offer you a discount. Contact us for more details!

This course is intended for graduates (or soon to be), designers, freelancers, technicians and engineers involved in: calculation, design, selection, manufacturing, safety, quality and maintenance of systems and equipment in industrial processes.

Previous knowledge of this subject is not required to attend to the course.

The main objective of this course is to transfer to participants the theoretical and practical skills required in projects, obtained from experience and sound engineering practices.

At the end of the course, participants will be able to design the main parts of a Pressure Vessel under all types of possible loadings, stored product, internal pressure, wind and earthquake among others. At the end of the course participants will:

To enroll in this course you have to follow the below steps:

Yes! Contact us indicating your needs and we will find the most convenient alternative for you.

To enroll a 3rd paty/more than one person you have to follow the below steps:

Please, send us your query and we will reply as soon as possible.

Average Rating

Detailed Rating

| Stars 5 |

|

21 |

| Stars 4 |

|

3 |

| Stars 3 |

|

0 |

| Stars 2 |

|

0 |

| Stars 1 |

|

0 |

You must be logged in to post a review.

| 978 Students |

| Video: English |

| Certificate of Training |

WhatsApp

WhatsApp

Brad N.

The course covers all expectations.

George N.

It is a great informative course.

Elisabeth O.

This is a very informative course it has met my expectations.

Yolanda R.

Thank you very much, its very helpful course.

Aitor A.

Overall good course.

Carlos B.

It was really a good experience with Arveng Training.

Jordan S.

Thanks for the course, some great content

Trung H.

Good learning experience, professional admin team and quick response

Kylie B.

Thank you for your help with completing this! I’ve learnt a lot.

Richard L.

The course was very good and concise.

Arry

The course serves as an exceptionally clear guide to learn about design of pressure vessel. I particularly appreciate the “ask the instructor” section of the course, where I could ask for clarification about the problem I found during my study.

Sander

This training was recommended to me by a project team member.

I am happy to have followed it and will surely recommend it to others.

Also I will keep an eye on your other courses, maybe for the future.

I like the way how the course is set up as self guided so that I could follow it at my own speed.

Thank you very much.

Kind regards, Sander.

Eduardo José

Very good course to learn the different stages of pressure vessels design and to acquire hand-on experience in using the ASME Section VII Div. 1.

Zaheer

Thank you for the wonderful course and the prompt response and clarification and guidance given throughout the course.

Rajasekhar

it was clearly understand in material well wrote as simple as passible to understand

Marcus

Course was really good, very good material for future reference. I enjoy it from beginning to the end.

Mohan Ram

Thank you for arvengtraining team and other dignitaries for give an such a great opportunity to have an such beautiful and important online class during this pandemic situation.

Ammar

The course was well designed and comprehensive. This course will be helpful for the field of pressure vessel design in accordance with ASME standards.

Morgan

I really enjoyed the course. At first I had some challenges navigating and using all the material but after Lesson 2 I was OK. Overall, the course is a great course and is value for money!!

Mihaela

After I have finished this course, I can see the big difference between the course online and the classrom courses. The biggest advantage of this one is at the end I have all explication in detail including exercises and not only PowerPoints slides as are in the other course. Great course

Munthir

The course is excellent and very informative. I would highly recommend this course to anyone who wants to increase their knowledge and experience.

dentor

I’ve looking for a course like this for quite some time now…it has exceeded my expectation honestly. Great job teacher, let’s keep in touch. Dennis.

paul_vance

Very useful calc sheets, jointly with real data sheets the best of the course. Thanks for everything arveng. Paul.

chris

Great training session. Despite the fact that I’ve always been very scheptical about online courses, I’ve really enjoyed it. 100% recommended.