The word “cryogenics” comes from two Greek words, “kryos” meaning icy cold, and “genes” meaning to form. The term cryogenics was first used in 1875 and has come into general usage since 1955. Cryogenic temperatures are normally considered as below (-)100ºC. One of the major benefits of handling gases in liquefied form is the enormous […]

Non-standard flanges will only be used in cases where pressure, temperature and size requirements exceed the capabilities of standard flanges. Keep in mind that non-standard flanges require calculation, design and special manufacturing procedures, which is why they are chosen only as a last resort. The most common such applications are large equipment flanges and heat […]

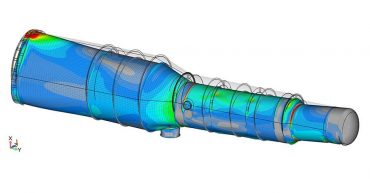

Fatigue analysis is often more demanded for Pressure Vessels and Shell and Tube Heat Exchangers (S&T). Operating conditions involving pressure and/or temperature cycles could result in a fatigue analysis requirement. Previous to perform a fatigue analysis is necessary to run screening criteria in order to check according to ASME VIII Div. 2 Ap. 5.5. if […]

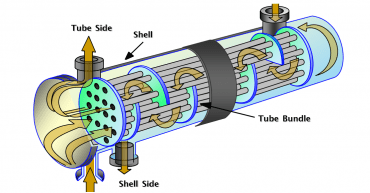

The term heat exchanger encompasses all devices used to transfer energy from one fluid to another. Some examples of this group are: radiators, water heaters, refrigeration batteries, evaporators, steam generators, etc. Direct contact heat exchangers, also known as mix exchangers, are devices where both fluids undergo a complete physical mixture. On the other hand, devices […]

External pressure can be caused in pressure vessels by a variety of conditions and circumstances. The design pressure may be less than atmospheric due to condensing gas or steam. Often vessels are design for some amount of external pressure, to allow for steam cleaning and the effects of the condensing steam. Other vessels are in […]