What are Self-reinforced nozzles?

- Posted by: César Boró Martín

- Category: Static Equipment

When referring to self-reinforced nozzles, it is generally assumed that the reinforcement to withstand the loads that affect the nozzle will be a constitutive part of the nozzle. This means that self-reinforced nozzles do not need auxiliary elements (like built up nozzles) to withstand design conditions and external loads.

On a practical level, self-reinforced nozzles are those that do not have any additional kind of reinforcement (pad) attached, and all the welds between its own components and between the nozzle and the vessel are full penetration type. Because of that, these nozzles could be named integrally reinforced as well.

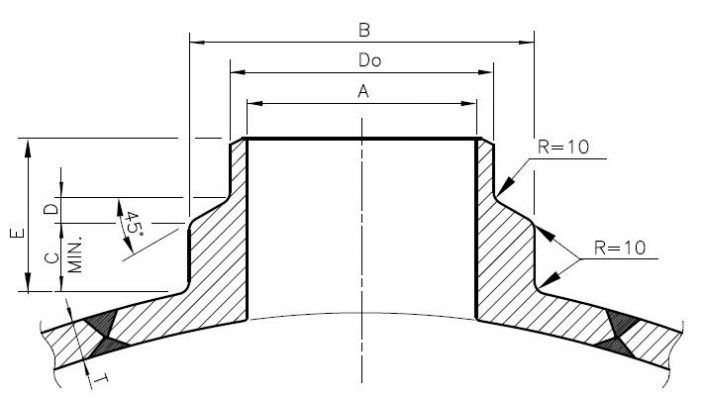

There are different configurations of self-reinforced nozzles. The most commonly used are the mentioned as follows: Long Welding Neck (LWN) or straight hub, variable hub thickness, and nozzles manufactured using a standardized thickness pipe.

Intuitively, it could be noted that usually self-reinforced nozzles imply an increase in the cost with respect to a non-self-reinforced type nozzle. Therefore, the reasons that lead the designer to choose one specific type among all the possibilities must be reasoned and fully scrutinized.

These reasons could depend on various factors such as pressure, temperature, the presence of variable loads (fatigue), high external loads consequence of being connected to a pipe, etc. Usually the requirements for the use of self-reinforced nozzles are included in the job specification belonging to the owners of industrial plants where those nozzles are in service or, on occasions, these requirements can be indicated in the licensor specification if applicable.

Due to the mentioned above, it is not possible to establish specific criteria regarding when to use this type of nozzles for all cases, but only some general guidelines that should be used as a first approach to consider in which scenarios self-reinforced nozzles should be considered as a design solution. Scenarios such as those in which design conditions include following effects are conducive to have to choose self-reinforced nozzles: the studied component must withstand variable loads (fatigue), tangential or inclined nozzles with respect to the vessel where nozzles are attached, lethal service, high pressure, high temperatures or pressure vessels with high thicknesses.

As already indicated, self-reinforced nozzles often go hand in hand with severe or critical service conditions. Because of it, it is convenient to mention that for this special kind of nozzles stress concentrators must be eliminated as much as possible.

For some design codes, the design and calculation criteria for self-reinforced nozzles and built up nozzles are not always the same. Requirements are more conservative for the latter case. As an example, consider the screening study of the ASME Section VIII Division 2, procedure to determine if a fatigue analysis is required. If a given equipment or any of its components is of integral configuration, it can withstand a higher number of variable loads than a non-integral configuration equipment, without being necessary to verify its strength against fatigue loads by means of a specific calculation.

Going back to the economic issue, even if it is totally clear that self-reinforced nozzles are the ideal solution for a given case, it should be considered that some self-reinforced nozzles configurations are fabricated from forged material. This means high economic costs, reason for which it is very important to optimize the design so that the cost does not increase excessively.

If you want to know more:

ASME VIII | Design of Pressure Vessels