IN THIS COURSE YOU WILL LEARN…

+ The codes applicable to piping design.

+ The different joining methods.

+ The different components of a system.

| 59 Students |

| Lectures: Available! |

| Video: English |

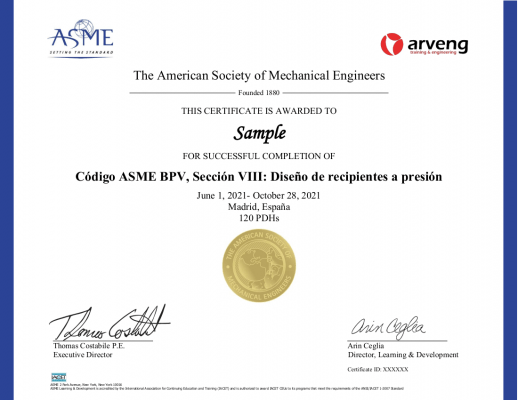

| Certificate of Training |

+ The codes applicable to piping design.

+ The different joining methods.

+ The different components of a system.

40 hours of self-guided training through our platform, without scheduled sessions, to progess at your own pace.

40 hours of self-guided training through our platform, with no scheduled sessions, the possibility to ask questions to the instructor, and progress at your own pace.

12 hours of live virtual classes with the instructor. Classes are primarily practical, focusing on the resolution of real-life cases.

Pay for this course in three interest-free installments with PayPal. More information.

This course is available in an in-company modality, tailored exclusively for your organization, adapting dates, schedules and contents to perfectly suit your needs. Reach out to us detailing the training needs of your team, and we will contact you to coordinate it.

Upon successful completion of the course participants will earn 40 PDH’s, equivalent to 4 CEU’s (Guided) or 12 PDH’s.

This recognition can only be obtained with the ASME certificate.

PDH: Professional Development Hour

CEU: Continuing Education Unit

*If you are not interested in obtaining an ASME certification after completing the course, we can offer you a discount. Contact us for more details!

This course is intended for graduates (or soon to be), designers, freelancers, technicians and engineers involved in: calculation, design, selection, manufacturing, safety, quality and maintenance of systems and equipment in industrial processes.

Previous knowledge of this subject is not required to attend to the course.

The main objective of this course is to transfer to participants the theoretical and practical skills required in projects, obtained from experience and sound engineering practices.

Establish pressure-temperature ranges

Calculation/selection of thicknesses per ASME B31

Selection of flanges, elbows, tees, etc.

Define piping class tapping table

To enroll in this course you have to follow the below steps:

Yes! Contact us indicating your needs and we will find the most convenient alternative for you.

To enroll a 3rd paty/more than one person you have to follow the below steps:

Please, send us your query and we will reply as soon as possible.

Average Rating

Detailed Rating

| Stars 5 |

|

5 |

| Stars 4 |

|

0 |

| Stars 3 |

|

0 |

| Stars 2 |

|

0 |

| Stars 1 |

|

0 |

You must be logged in to post a review.

| 59 Students |

| Lectures: Available! |

| Video: English |

| Certificate of Training |

WhatsApp

WhatsApp

Samantha H.

The course has been very practical, interesting, and has met my expectations. Happy with the attention received, and grateful.

Nilson P.

The course has met my needs. I recommend the course.

Willy T.

Very satisfied with the result. I had already worked with the tool before but it has been an excellent way to get back in touch.

Brenda F.

Absolutely recommended both in content and attention.

Carol G.

The structure of the course and the attention of the tutor have been excellent.