Refinery process heaters

How to maintain the efficiency of these large energy consumers?

Process heaters are probably the most critical pieces of equipment within refineries and petrochemical plants, as they consume large volumes of fossil fuels and emit proportional amounts of CO2 into the atmosphere.

Profit margins may be at stake if heaters emissions are higher, thermal efficiency lower, and process run cycles shorter than those stipulated in equipment design.

Mechanical integrity

Preserving the integrity of direct-fired heaters is just as important as saving fuel and reducing their carbon footprint.

Activities relevant to mechanical integrity span the entire heater life cycle, including engineering, construction, and spare parts, as well as ongoing operation and equipment maintenance. The implementation of safe and efficient operating conditions greatly contributes to the preservation of the mechanical integrity of process heaters.

Since direct fired heaters handle very hot fluid streams, open flames, very high combustion gas temperatures, etc., they are considered the most critical and risky equipment in the daily operations of refineries. Additionally, in many circumstances, the furnaces operate continuously for several years, processing very high loads.

Achieving reasonable and reliable operation during extended process runs is only possible if the heaters are subject to a rigorous operational, maintenance and inspection strategy.

Periodic inspections, performance evaluations, and subsequent equipment tuning are fundamental actions aimed at operational optimization of process heaters.

- Periodic inspections

Conducting an inspection of a process heater requires careful planning, starting with the detailed study of the equipment design sheets and relevant operational data, and including details such as the location of tubes with installed thermocouples, the radiant arc temperature sensor, and the combustion gas sampling points.

Additionally, the combustion engineer must collect and review previous furnace operating data and reports, prepare a checklist for his/her own evaluation and, finally, procure his/her personal protective equipment (PPE) as well as inspection instruments.

Inspection activities shall begin in the plant Control Room and they must include:

- Collection of relevant process operational data:

- Inlet and outlet process fluid temperatures (TI & TO)

- Process fluid mass flow per pass

- Volumetric flow of fuel gas per cell

- Radiant arc (TArch) and stack (TSt) temperatures

- Radiant wall tube metal temperatures (TMT)

- Draft at burner, arch and stack levels

- Percent opening of stack damper

- Detailed observation of flame quality of each burner

- Close observation of the mechanical integrity of the most critical individual components of the heater

- Coils and supports

- Burners

- Refractories

Performance evaluation

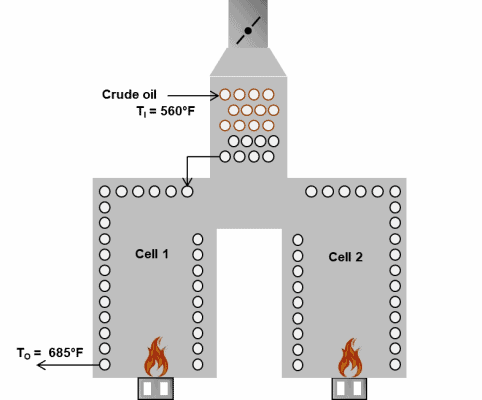

Let us consider the thermal and operational evaluation of the natural draft heater (FH-01) operating in an atmospheric distillation unit and designed to process 250,000 Bbl/d of crude oil, increasing its temperature from 560 to 685°F. A schematic diagram of the furnace is shown in the figure below.

Crude oil heater diagram FH-01 (Design TI and TO)

Crude oil heater diagram FH-01 (Design TI and TO)

This cabin type heater consists of two radiant cells, each equipped with 66 horizontal tubes located along both cell walls and distributed in 12 passes. Each cell is equipped with 20 circular low NOx burners, aligned in the center of the floor.

The radiant shield consists of 18 bare tubes while the convective section houses 18 bare tubes and 72 tubes provided with solid circular fins, for the flow of crude oil, and 24 additional tubes, also with solid circular fins, for the steam superheating service.

The heater burners consume refinery gas (lower heating value, PCI, 1.030 Btu/pie3). The thermal efficiency of the heater, according to the design, is 82.2%, based on the PCI.

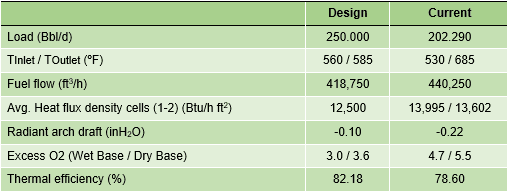

The heater performance evaluation showed the following results:

- Total crude load to the heater was 202,290 Bbl/d, relatively well distributed between its passes (17,500-16,350 Bbl/pass)

- Crude oil inlet temperature (TI) was 530°F, and the crude oil outlet temperature (TO) coincided with the design value of 685°F

- Fuel gas consumption, whose PCI was measured as 1,095 Btu/ft3, totaled 440,250 ft3/h distributed evenly between both cells

- Radiant arch draft, flue gas temperature, and excess oxygen measured in the radiant arch averaged -0.22 inH2O; 1,186°F and 4.7% (WB) respectively

- The flue gas temperature was 690°F and the thermal efficiency was calculated as 78.6%

The following table shows a comparison between current and design operating conditions.

Comparison between operating conditions

Even processing 20% less than the design load, the fact that the inlet temperature (TI) was 30ºF lower than the design value imposed an additional load on this furnace, recording radiant heat flux densities of 13.995 y 13.602 Btu/h ft2, clearly higher than the design value of 12.500 Btu/h ft2.

Generally, any heater can handle high heat fluxes for limited periods of time. However, operational actions must be taken to alleviate its operation and keep fuel consumption under control.

In this case, however, the poor control of the furnace draft, which showed values in the radiant arc of -0.22 inH2O, resulted in an oxygen concentration of 4.7%, WB in the combustion gases, clearly higher than the design value. This fact generated greater fuel consumption, to compensate for the loss of heat transferred to the additional mass of air entering the heater.

An obvious consequence of these events is the increase in the temperature of the stack gases and the decrease in the heater thermal efficiency by approximately 3.6 percentage points.

Restoring this crude oil furnace to a desirable operating condition involves some basic steps that do not necessarily entail unusual expenses.

Assuming that the burners do not produce abnormal flames that impinge on the radiant tubes and that their air registers do not present any mechanical impediment, the logical operational solution should be an appropriate control of the draft so that it coincides or approaches the recommended value of -0.10 inH2O.

In the second part of this article the procedure described in this DRAFT diagram will be described and put into practice. Subsequently, the exercise will be resumed to discuss the actions to take to increase the thermal efficiency of the FH-01 furnace and estimate the corresponding fuel savings.

If you want to know more:

WhatsApp

WhatsApp