The design temperature, along with the design pressure, fluid characterization and other technical-economical requirements, is a critical parameter in the design and material selection of process equipment, instrumentation and piping.

The selection criteria differ slightly depending on the engineering practices, but generally consist of assigning a design margin to the maximum (and minimum) normal operating temperature, which is usually around 25 ºC, being that margin smaller at high and low temperatures in order to avoid an unnecessary selection of more expensive materials. The design temperature must also include any alternative working condition (start-up, shut-down, drying, …).

If there are heat exchangers in the system, a criterion has to be followed to reduce the design temperature accordingly to the normal operating in the process, and so to avoid extending more restrictive design conditions than required in the downstream system. It may have a high economical impact if there are several equipment in series.

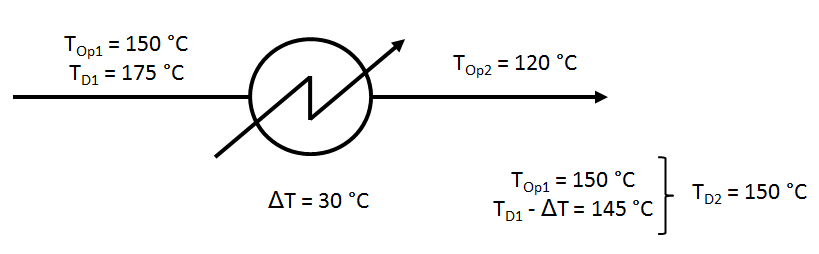

One of the most commonly used criterion in engineering is to select the highest of the following temperatures as the design temperature of the system downstream the heat exchanger (TOp = operating temperature; TD = design temperature; ΔT = temperature difference from inlet to outlet in normal conditions):

- TOp1 = TD2

- TD1 – ΔT = TD2

WhatsApp

WhatsApp