Boiler feed water and boiler water treatment

- Posted by: María García

- Category: Process Engineering

For industrial companies using a boiler for its facility, some type of boiler feed water treatment system is usually necessary to ensure an efficient process and quality steam generation. The most appropriate boiler feed water treatment system will help the facility avoid costly plant downtime, expensive maintenance fees, and boiler failure as a result of scaling, corrosion, and fouling of the boiler and downstream equipment. Water treatment shall be focused in impurities (suspended solids, dissolved solids, organic matter, etc) reduction or removal by different treatments (filtration, ion exchange demineralization, reverse osmosis, etc).

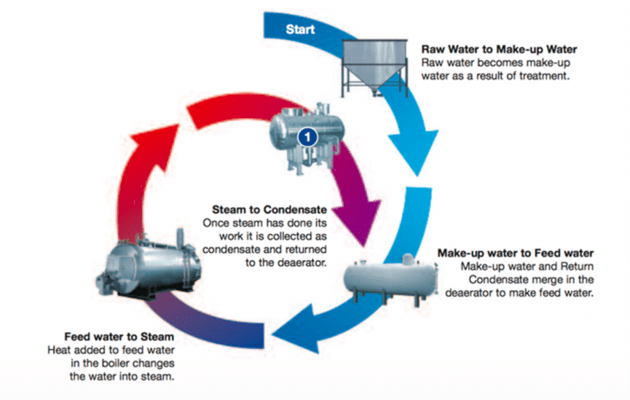

Figure 1. The Boiler water cycle

BFW (boiler feed water) is a mixture of make up water (added to compensate for losses in the steam circuit) and condensate that requires a specific purity to prevent corrosion in boiler, steam and condensate systems as well as to reduce scale and to have an economic boiler operation without carryover.

The deposition of crystalline precipitates on the walls of the boiler interferes with heat transfer and may cause hot spots, leading to local overheating. The less heat they conduct, the more dangerous they are.

Water treatment and conditioning of BFW must meet the following three priority targets:

- Maintaining heat exchange by preventing scaling and the formation of deposits on walls

- Protection against corrosion

- Quality of the vapor produced in boilers

The necessary type of make-up water treatment for the water steam-steam circuit depends on:

- Raw water quality (e.g. hardness, alkalinity, conductivity, silica content, turbidity)

- Amount and quality of condensate return to the BFW

- Specifications of the BFW and boiler water (depending on boiler type, boiler pressure, max. heat transfer)

- Specifications of the stream produced (e.g.super-heater/turbine operation, high quality stem for production processes, corrosion in the steam and condensate system)

- Economic and ecologic requirements (e.g. blowdown rate (1), effluent requirements)

Low pressure boilers do not require the same quality than high pressure boilers. In this way, the boiler feed water treatment required in such case, will differ considerably. A low pressure boiler can usually tolerate high feed water hardness with proper treatment while virtually all impurities must be removed from water used in high pressure boilers, especially in those used for power generation. Only relatively wide ranges can be given as to maximum levels of alkalis, salt, silica, phosphates etc, in relation to working pressure.

The allowable concentration of impurities in boiler water determines the type of boiler feedwater treatment required. Then, the presence of impurities in the boiler water must be properly controlled with the blowdown rates.

Harmonized standards are widely used for the requirements for boiler feed water and boiler water quality. The stated goal of these standards is to uphold minimum requirements for a safe boiler operation.

—

(1) Blowdown: Boiler blowdown is the removal of water from a boiler to control boiler water parameters within prescribed limits to minimize scale, corrosion, carryover, and other specific problems. Blowdown is also used to remove suspended solids present in the system. These solids are caused by feedwater contamination, by internal chemical treatment precipitates, or by exceeding the solubility limits of otherwise soluble salts.

If you want to know more:

WhatsApp

WhatsApp