Pipes are the most delicate components in any process plant, they are also the busiest entities. Piping Systems are subjected to almost all kinds of loads, intentional or unintentional. It is very important to take note of all potential loads that a piping system would encounter during operation as well as during other stages in the life cycle of a process plant. Ignoring any such load while designing, erecting, hydro-testing, start-up shut-down, normal operation, maintenance etc. can lead to inadequate design of a piping system. The system may fail on the first occurrence of this overlooked load. Failure of a piping system may trigger a Domino effect and cause a major disaster.

As the pipe temperature changes from the installation condition to the operating condition, it expands or contracts. In the general term, both cases are called thermal expansion. When a pipe expands it has the potential of generating enormous force and stress in the system. However, if the piping is flexible enough, the expansion can be absorbed without creating undue force or stress. Providing the proper flexibility is one of the major tasks in the design of piping systems.

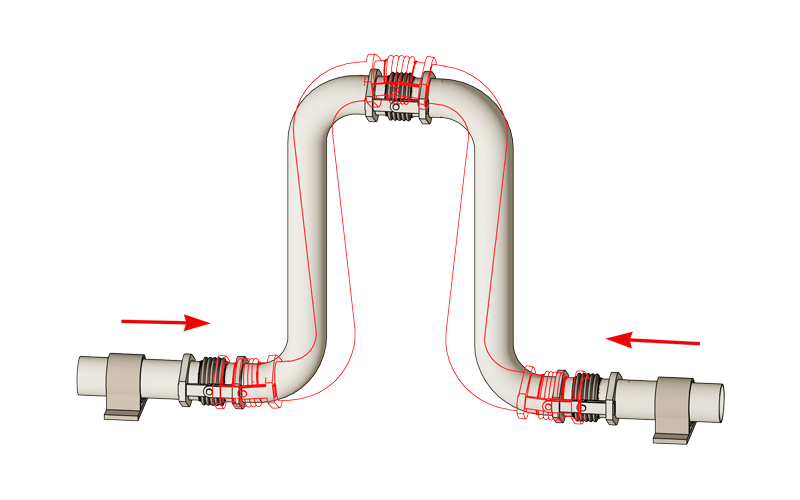

Piping is used to convey a certain amount of fluid from one point to another. It is obvious that the shorter the pipe is used the lesser the capital expenditure is required. Long pipe runs may also generate excessive pressure drop making it unsuitable for the proper operation. However, the direct shortest layout generally is not acceptable for absorbing the thermal expansion. Flexibility analysis is done on the piping system to study its behaviour when its temperature changes from ambient to operating, so as to arrive to the most economical layout with adequate safety. Piping flexibility is provided in many different ways.

Pipes bend, even under their own weight. The longer the pipe, the easier it is to bend. If a pipe is bent within its elastic limit (no permanent deformation), it will behave like a spring and return to its original shape after the load is removed. If the elbows and anchors on a pipe system are arranged to allow movement, the forces will be much less than a straight run. Also, the turns and offsets needed for running the pipe from one point to another provides some flexibility as well. This inherent flexibility may or may not be sufficient depending on the individual cases.

Additional flexibility can be provided by adding expansion loops or expansion joints.

If you want to know more:

Piping Systems in Industrial Plants: I

WhatsApp

WhatsApp