As a general rule, storage tanks operate at atmospheric or very low pressures. A fundamental analysis in the design of storage tanks, associated with their protection and safety, is the design of the elements against overpressure and vacuum. The most commonly used protection elements in storage tanks are the vents, along with additional pressure relief valves or the use of a frangible joint of the tank roof.

The sizing of vents in storage tanks is based on the API 2000 Standard: “Venting Atmospheric and Low-Pressure Storage Tanks”. This standard covers the operating requirements of storage tanks at pressures up to 15 psig.

To perform the analysis, a series of values of temperatures, latitudes, liquid flows, temperature changes, possible fire scenarios, etc. will be required.

The main causes that can generate an overpressure or vacuum in the storage tank are the following:

- Filling and/or emptying the tank.

- Changes in pressure and temperature in the environment.

- Exposure of the tank to fire, which generates an increase in the pressure inside the tank.

- Failures or blockages during operation.

When some of these situations described above occur, a pressure relief or a vacuum inhalation will be required and must be calculated using the requirements indicated in the API 2000 standard.

The scenarios that should be considered when calculating the capacity of the vent in a storage tank are the following:

- Tank inbreathing due to liquid leakage/drainage (volumetric displacement, liquid transfer).

- Tank inbreathing due to the condensation of vapors in the space of the tank (thermal effect). A decrease in the temperature of the environment – Thermal Inbreathing.

- Tank outbreathing due to liquid entering into the tank (volumetric displacement, liquid transfer).

- Tank outbreathing due to the evaporation of liquids in the space of the tank (thermal effect). An increase in the temperature of the environment – Thermal Outbreathing

- Emergency venting due to fire exposure.

The capacities of the previously indicated scenarios will be combined to obtain the total venting capacities required by both inbreathing and outbreathing.

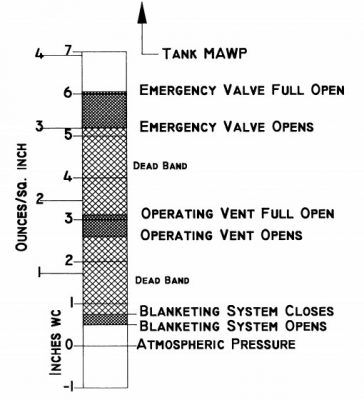

The diagram below shows the different working pressure ranges of a storage tank and the times at which emergency devices, vents, and pressure relief valves operate.

Diagram of pressures in Storage Tanks

In addition to the calculation indicated above, the API 2000 standard suggests the use of flame arresters in storage tanks containing flammable products such as hydrocarbons. The function of this device is to prevent the entry of flames into the tank in the event of an external fire. When the tank is in fire-case, it will be necessary to perform the required calculations to size the vent during this scenario.

Flame arrester

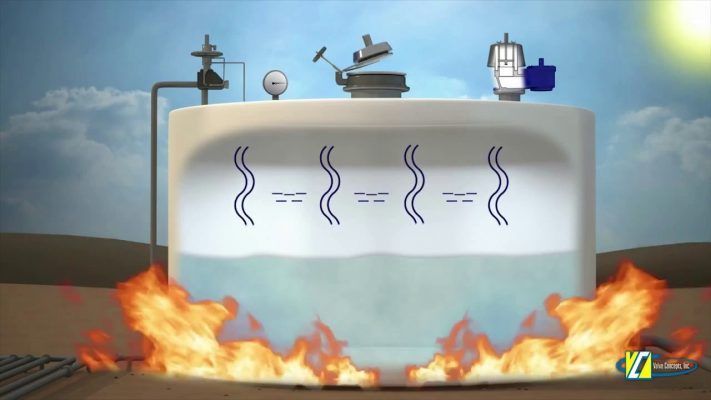

The API 650 Code allows the use of a frangible roof joint as a preventive measure against overpressures and emergency vents, but this option should only be considered when there is a possibility of fire.

Overpressure in storage tank due to fire

Blanketing

Blanketing valves are used in storage tanks in order to minimize the risks associated with the stored flammable product, reduce product contamination by generating an air chamber inside the tank or to reduce evaporation losses.

The procedure consists of installing a valve that generates a cloud of an inert gas such as nitrogen.

The API 2000 standard, in Annex F, indicates guidelines to be followed for the sizing of a protection system with an inert gas.

Tank Blanketing

If you want to know more:

WhatsApp

WhatsApp