Pipeline codification in P&ID’s

- Posted by: Ignacio Vilas

- Category: Piping Process Engineering

No Comments

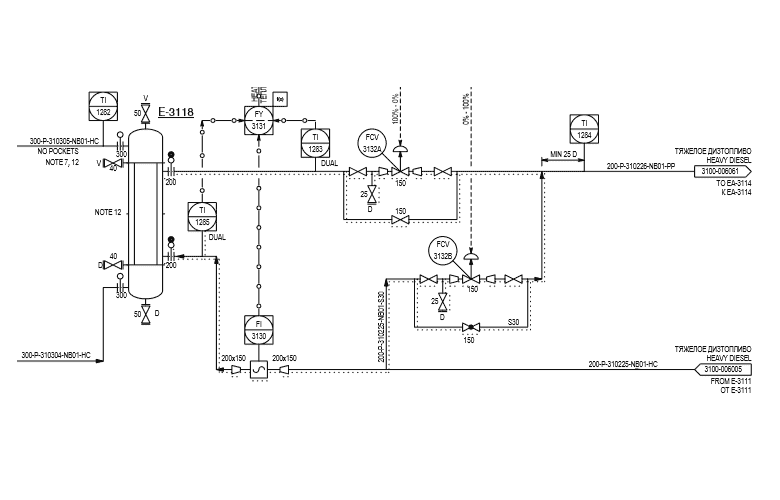

All pipes are represented in Piping and Instrumentation Diagrams (P&IDs) by lines, with an alphanumeric coding that allows identifying them for subsequent design (routing, thermal stress analysis, supporting, etc.) and purchase.

There are no rules to stablish universal coding; they depend on each project. Although they include basically the same information, the way they are represented differs. As an example, it is shown a typical line numbering with its characteristic information:

AA-BB-CC-DDDD-EEEE-FF

(e.g.: 4”-FG-03-0035-A1A1-HC)

- AA: nominal diameter, in inches(“) if ANSI rules apply or millimetres if we talk about EN-ISO. This diameter is not necessarily coincident with the pipe external or internal diameter, which will depend on the schedule, material type and rating (e.g.: 4 inches)

- BB: fluid code, to distinguish the service for which the pipe is used for (e.g.: fuel gas)

- CC: Unit number, since several Plants may exist in the same industrial complex (e.g.: Unit number 03).

- DDDD: line number. They are assigned sequentially (e.g.: 0035).

- EEEE: pipe class. It collects characteristics such as material type, rating, flange type and corrosion allowance (e.g.: carbon steel, 150#, FF flanges, C.A. 1.6 mm).

- FF: insulation code, due to different requirements such as heat or cold conservation, tracing, jacketing, personal protection, etc. (e.g.: heat conservation).

If you want to know more:

Piping Systems in Industrial Plants: I

Author:Ignacio Vilas

Más de ocho (8) años de experiencia profesional, principalmente en proyectos multidisciplinarios de Ingeniería en los sectores de Refino y Petroquímica, desempeñando labores de ingeniero de procesos. Formación profesional previa en Planta, en empresas de Tratamiento de Aguas Residuales Urbanas y de Celulosa para fabricación de papel.

Experiencia en el desarrollo de proyectos EPC a nivel internacional, realizando tareas de diseño, cálculo, validación, optimización, trato con clientes y coordinación y supervisión de ingenieros de menor experiencia; todo ello orientado y comprometido a cumplir en plazo, calidad, coste, alcance y planificación los requerimientos de los proyectos.

Dominio de normas internacionales y manejo de especificaciones de clientes de ámbito internacional (REPSOL, TÜPRAS, DOW, SAUDI ARAMCO, NEFTEGAZINDUSTRIYA, GAZPROM).

WhatsApp

WhatsApp