Types of Supports and Guides in Industrial Piping Systems

- Posted by: arvengtraining

- Category: Piping

In the design of piping systems for industrial plants, supports and guides are key elements to ensure mechanical integrity, operability, and the service life of the system. Based on our experience in piping engineering, inadequate support design can lead to excessive stresses, flange leaks, overloads on connected equipment, or recurring vibration and maintenance issues.

Support design should not be considered an isolated discipline, but rather a fundamental part of the system flexibility analysis. Once routing has been defined and stress calculations have been performed, it is essential to properly implement the specified restraints through actual supports, correctly selected and located in accordance with good engineering practices and recognized standards.

Function and objectives of piping supports

The primary objective of piping supports is to safely transfer system loads to structures, equipment, or foundations. Their functions include supporting the weight of the pipe, conveyed fluid, insulation, and fittings; controlling displacements due to thermal expansion; limiting forces and moments transmitted to equipment; absorbing hydraulic thrusts; and resisting occasional loads such as wind or seismic actions.

One of the most critical functions is the control of thermal displacements. In high-temperature systems, misinterpretation of restraints can generate stress concentrations or transmit inadmissible loads to equipment nozzles, compromising plant safety.

General classification of supports

From a piping engineering perspective, supports can be classified according to different criteria. A first classification distinguishes between primary supports, which are directly attached to the pipe, and secondary supports, which are fixed to the structure or foundation and are responsible for transmitting the load.

Another relevant classification is based on construction type: standard supports, commercially available with tabulated allowable loads; special supports, designed for specific applications; and structural supports, such as frames or pipe racks, which require dedicated design by structural specialists. Whenever project conditions allow, it is recommended to prioritize standard and special supports due to their reliability, cost efficiency, and ease of installation.

Rigid supports: movement control

Rigid supports are those that restrain one or more degrees of freedom of the pipe, preventing displacement in the restrained direction. They are used when it is necessary to resist weight loads, occasional loads, or to control thermal expansion toward undesired areas.

Common examples include simple supports, which provide vertical restraint and transfer weight to the structure; hangers, which suspend the pipe using rods or bars; and guides, which restrain transverse displacements while allowing controlled axial movement.

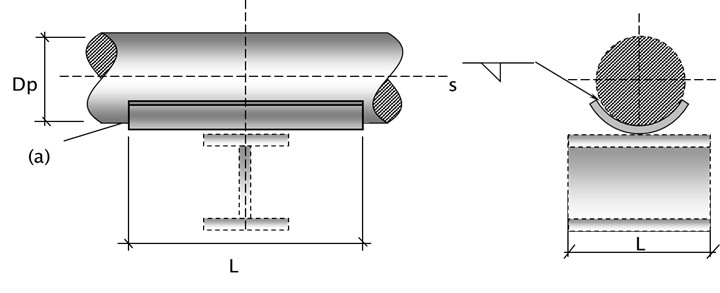

Simple support typical configuration

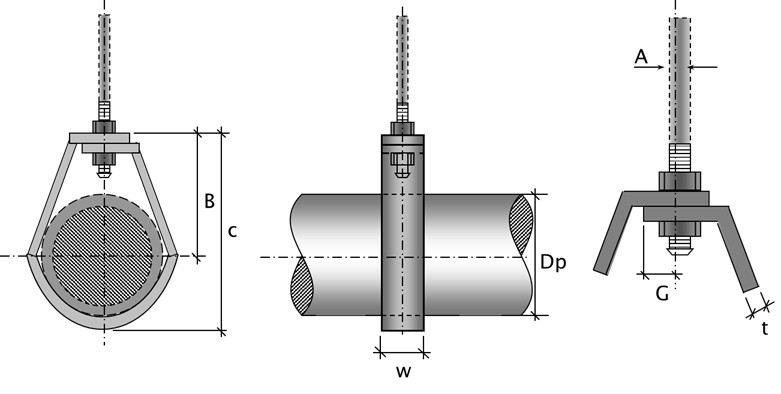

Hangers typical configuration

Special attention must be given to anchors. A directional anchor prevents axial displacement while allowing rotations, whereas a full anchor restrains all movements and rotations, becoming one of the most critical points in the system. Their location must be carefully defined during flexibility analysis, as it governs the global behavior of the line.

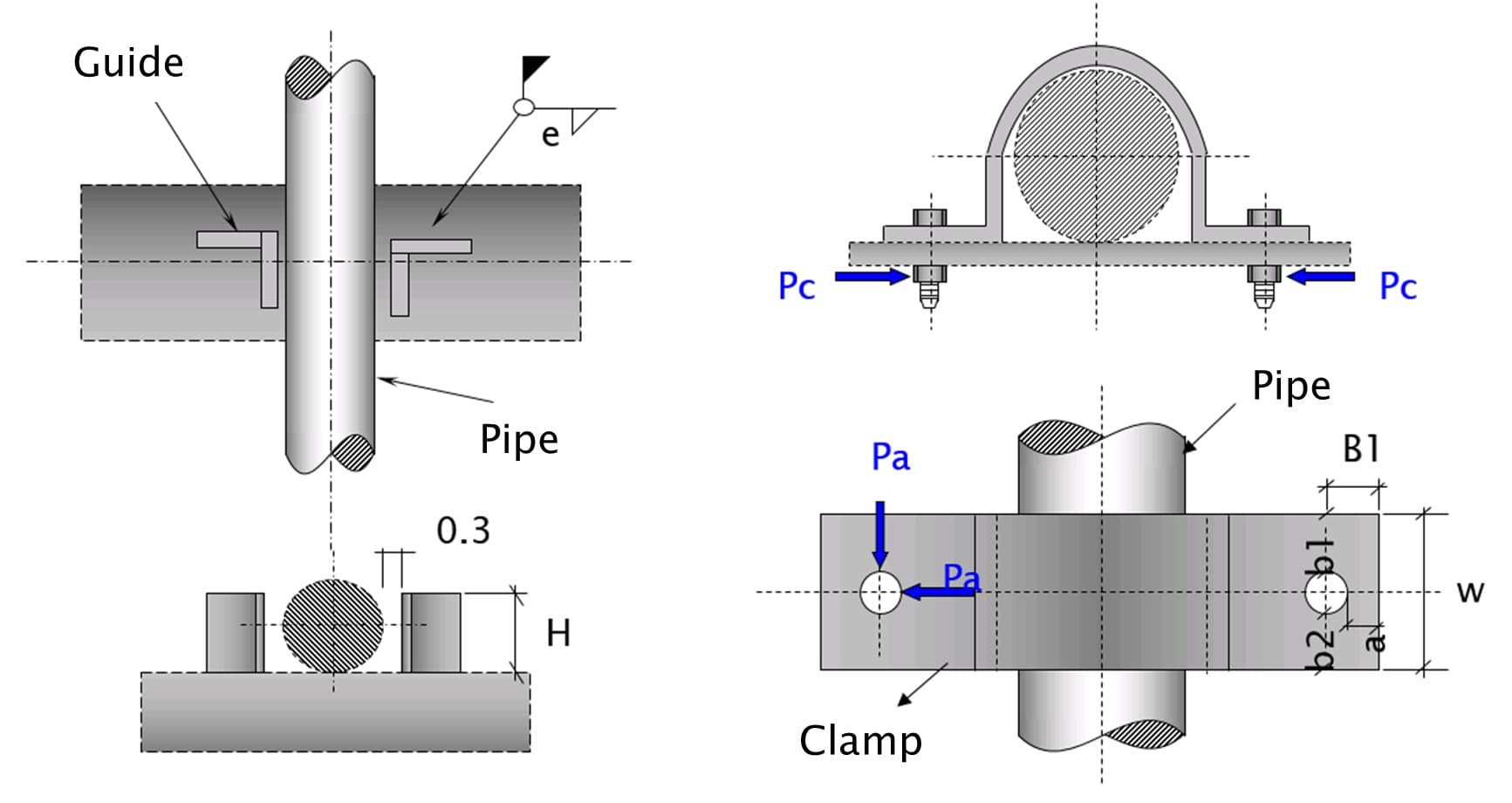

Guides in piping systems: function and practical application

Guides play an essential role in the controlled distribution of thermal expansion displacements. They allow pipe movement in a single direction, typically axial, while preventing lateral displacements that could induce undesired stresses or mechanical interferences.

In industrial practice, guides are commonly implemented using pipe shoes with lateral stops or sliding supports with transverse restraint. A frequent mistake is over-restraining the line, unintentionally turning a guide into an anchor, which can significantly increase thermal stresses. Therefore, it is essential to respect the clearances (gaps) specified in the flexibility isometric drawings.

Typical guide configurations

Flexible supports: displacement absorption

When vertical displacements due to thermal expansion are significant, rigid supports are no longer a viable solution. In such cases, flexible supports are used, mainly variable or constant load springs.

Variable load springs are applied when the load variation between cold and hot conditions does not exceed 25% and displacements are moderate. They are commonly used on vertical hot lines or as the first support after tank connections to absorb differential settlements.

Constant load springs, on the other hand, maintain an almost constant force applied to the pipe throughout its travel. They are reserved for critical piping, high-temperature systems with large displacements, or when sensitive connections must be protected. Although their cost is higher, proper application significantly reduces stresses transmitted to the system.

Applicable codes and good engineering practices

Support design and selection are based on strength of materials principles and widely accepted international standards. Among the most relevant are the Manufacturers Standardization Society (MSS) standards, such as MSS-SP-58 and MSS-SP-69, which define support types, selection criteria, and application guidelines.

Additionally, codes such as ASME B31.1 provide indicative tables for maximum support spacing based on pipe diameter, fluid, and operating conditions. These references must always be complemented by system-specific analysis and by client or project specifications.

Common mistakes and recommendations

Based on our experience, common mistakes include supporting pipes on valves or fittings, locating supports in areas with high local stresses such as tight elbows, or failing to properly consider hydrostatic test conditions, particularly for flexible supports.

We recommend following an orderly design sequence: first evaluating sustained loads, then test conditions, followed by thermal loads, and finally occasional actions such as wind, seismic loads, or vibrations. Close coordination between the flexibility analyst and the support designer is also essential to avoid inconsistencies between the analytical model and the constructed solution.

Conclusion

Supports and guides in piping systems are not merely auxiliary elements, but fundamental structural components for the proper operation of an industrial plant. Proper design, based on rigorous flexibility analysis, recognized standards, and sound engineering practices, allows displacements to be controlled, stresses to be limited, and system reliability to be ensured throughout its service life.

At Arveng, we believe that pipe support design must be addressed in an integrated manner from the early stages of the project, understanding the global behavior of the system and correctly implementing the defined restraints. Only in this way can safe, efficient, and maintainable installations be achieved.

WhatsApp

WhatsApp